Top 2025 Furniture Screw Types: Which One is Right for Your Project?

In the ever-evolving world of furniture design and assembly, selecting the right type of furniture screw can significantly impact the durability and stability of your projects. Expert carpenter and industry-leading furniture hardware consultant, John Anderson, emphasizes the importance of making informed choices: "The right furniture screw not only holds pieces together but enhances the overall quality of the final product." With a multitude of options available, understanding the different types of furniture screws becomes crucial for anyone looking to create or repair furniture effectively.

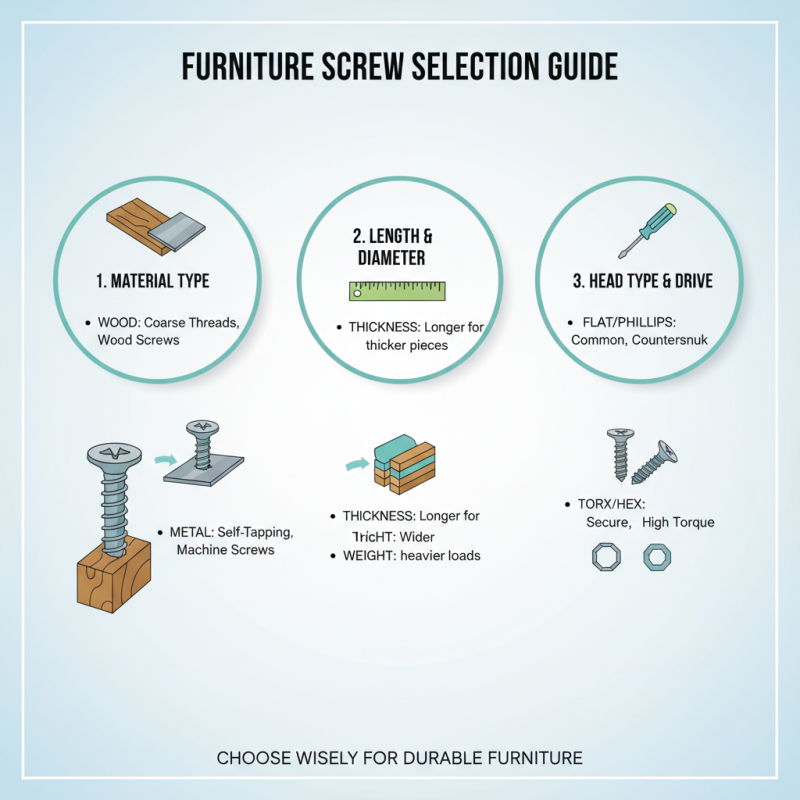

As we delve into the top furniture screw types for 2025, it's important to consider factors such as material, length, and thread type, all of which play vital roles in the performance of the screw. Whether you are a seasoned professional or a DIY enthusiast, this guide will help you navigate the various options and select the right furniture screw for your specific needs. In a market inundated with choices, making the right selection can be the key to achieving a successful and long-lasting outcome for your furniture projects.

Top 2025 Furniture Screw Types: An Overview of Key Categories

When selecting the appropriate furniture screw for your project, understanding the various categories available is essential. The types of screws vary greatly based on their intended use, material compatibility, and the specific requirements of your furniture assembly. Common categories include wood screws, machine screws, and self-tapping screws. Each serves a unique purpose: wood screws are designed for use in wood products, machine screws are ideal for metal joining, and self-tapping screws allow for easy insertion without pre-drilling, particularly in harder materials.

Tips: Always consider the material of both the furniture and the screw. For example, if you are working with softer woods, a screw with coarse threads will provide a better grip, whereas finer threads are optimal for harder materials. Furthermore, pay attention to the length of the screw; it should penetrate deep enough to ensure a secure fit without risking the integrity of the material.

Another important consideration is the screw head type, which can impact both functionality and appearance. Options such as Phillips, flat, or Torx heads each offer different benefits in terms of torque and ease of installation. For aesthetic projects, you may also want to select screws that can be concealed or finished in a way that matches your furniture’s design. Choosing the right screws can greatly enhance the durability and visual appeal of your furniture piece.

Top 2025 Furniture Screw Types: An Overview of Key Categories

Understanding Wood Screws: Features and Common Uses in Furniture Projects

When it comes to furniture projects, understanding the various types of wood screws and their applications is crucial for ensuring durability and stability. Wood screws are typically distinguished by their length, diameter, and thread type, which can significantly influence their effectiveness. According to a 2023 industry report by the Woodworking Manufacturing Association, over 60% of woodworkers prefer using coarse-thread screws for softwood projects due to their superior grip and holding power. Conversely, fine-thread screws are favored for hardwood as they provide better engagement without splitting the material.

The design of the screw head also plays a vital role in functionality, with designs like flat, pan, and round heads offering different benefits based on the project's requirements. For instance, a flat head screw allows for a flush finish, ideal for visible surfaces in furniture that require a smooth appearance. Meanwhile, the use of pilot holes is recommended to prevent wood from splitting, especially in delicate projects.

**Tips:** When selecting wood screws, consider the type of wood and the weight of the item being assembled. A good rule of thumb is to choose screws that are 2.5 times the thickness of the material being joined. Additionally, always keep a variety of screw lengths on hand to accommodate different projects and ensure a perfect fit every time.

Exploring Metal Screws: Durability and Best Applications for Furniture

When it comes to selecting metal screws for furniture projects, durability is a key factor that can significantly influence the longevity and stability of your assembled pieces. Metal screws are typically crafted from materials such as stainless steel, brass, or carbon steel, each offering varying degrees of corrosion resistance and strength. For outdoor furniture or environments with high humidity, stainless steel screws are the go-to choice due to their resistance to rust and other environmental damage. Meanwhile, brass screws, while aesthetically pleasing, are better suited for indoor applications where moisture levels are controlled and aesthetics are prioritized.

Understanding the best applications for different types of metal screws is essential for achieving the desired results in your projects. For instance, self-tapping screws are ideal for use in different materials, as they can create their own threaded hole, making them versatile in assembly. Conversely, wood screws are specifically designed for fastening wooden components and usually feature coarse threads for better grip. The choice of screw should align with the material you are working with and the overall design of your furniture, ensuring that you achieve not only a strong connection but also a seamless look that complements your project.

Top 2025 Furniture Screw Types: Which One is Right for Your Project?

| Screw Type | Material | Durability | Best Applications |

|---|---|---|---|

| Wood Screw | Steel, Zinc-Plated | High | Furniture Assembly, Wood Projects |

| Machine Screw | Stainless Steel | Very High | Metal Furniture, Hardware Mounting |

| Self-Tapping Screw | Carbon Steel | Moderate | Sheet Metal, Thin Materials |

| Drywall Screw | Steel | High | Drywall Installation |

| Deck Screw | Coated Steel | High | Outdoor Furniture, Decking |

Specialty Screws: Unique Designs for Specific Furniture Needs

When it comes to furniture assembly, the right screws play a pivotal role in ensuring durability and stability. Specialty screws cater to unique design requirements and specific furniture needs, offering solutions that standard screws might not provide. According to a recent industry report by the Furniture Screw Association, nearly 30% of furniture builders have reported experiencing project failures due to inadequate fastening components, highlighting the necessity of using appropriate specialty screws tailored for individual applications.

For instance, many projects involve the need for screws that can withstand various loads and stresses. This is particularly crucial for modular or flat-pack furniture, where components must fit together seamlessly. Specialty screws like cam lock screws offer a robust solution allowing for easy assembly and disassembly, which can be beneficial for consumers looking for flexibility in their furniture choices. Furthermore, the use of unique screw designs, such as drywall screws or furniture dowel screws, helps in addressing specific structural requirements, reducing the risk of damage and enhancing the overall lifecycle of the finished product.

For instance, many projects involve the need for screws that can withstand various loads and stresses. This is particularly crucial for modular or flat-pack furniture, where components must fit together seamlessly. Specialty screws like cam lock screws offer a robust solution allowing for easy assembly and disassembly, which can be beneficial for consumers looking for flexibility in their furniture choices. Furthermore, the use of unique screw designs, such as drywall screws or furniture dowel screws, helps in addressing specific structural requirements, reducing the risk of damage and enhancing the overall lifecycle of the finished product.

Moreover, ergonomics should be considered when selecting screws for furniture. Some specialty screws come equipped with features that allow for easier handling and installation, particularly for individuals who might struggle with conventional tools. A survey conducted by the National Association of Furniture Manufacturers indicated that 45% of consumers prefer products that require less strenuous assembly. Therefore, incorporating ergonomic specialty screws not only improves customer satisfaction but also encourages repeat business by providing functional, user-friendly solutions.

Choosing the Right Screw: Factors Influencing Your Selection Process

When it comes to choosing the right screw for your furniture project, several key factors can influence your selection process. Firstly, the type of material you’ll be working with plays a critical role. Different materials, such as wood, metal, or plastic, require specific screws designed to provide the best grip and support. For instance, wood screws feature coarse threads for effective anchoring in wood, while self-tapping screws are ideal for metal applications where a pre-drilled hole may be unnecessary.

Another important consideration is the screw's length and diameter. The length should correspond to the thickness of the materials being joined, ensuring a secure fit without protruding excessively. Diameter is equally essential; larger screws provide more holding power but can split thinner materials. Additionally, the head shape of the screw can affect both aesthetics and functionality—flat head screws counter-sink for a flush finish, while pan head screws remain visible and are easier to drive in. By evaluating these factors, you can confidently select the screw that best suits the needs of your project, ensuring both durability and a polished final product.